Product Overview

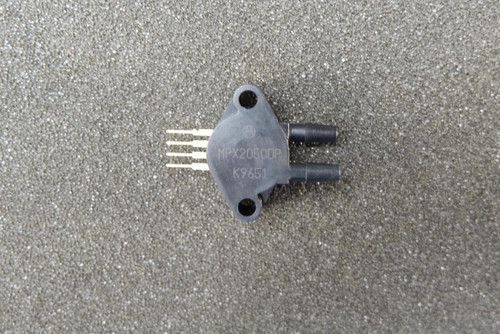

Compact Differential Pressure Sensor, Temperature Compensated (Unused NOS)

This compact board-mount pressure sensor converts low differential pressure into a stable millivolt signal for precision control systems. Built for wet or dry media, it fits tight assemblies where consistent sensing matters. A practical tip: plan clean tubing runs and a low-noise amplifier for best results in PSI / kPa measurement ranges.

Product Condition

Unused, New Old Stock. Clean, well-preserved inventory that has not been placed into service.

Product Overview

The 26PCAFA6D is part of Honeywell’s 26PC Series of solid-state pressure sensors known for stability and interchangeability. This model provides a temperature-compensated, calibrated bridge output intended for external signal conditioning. Its compact, through-hole package with dual ports supports differential or gauge pressure measurement in space-constrained designs.

Key Features

- Low-range differential pressure sensing up to 1 psi

- Temperature compensated and factory calibrated null and span

- Unamplified millivolt bridge output

- True wet/wet differential sensing capability

- Suitable for vacuum or positive pressure measurement

- Compact, board-mount through-hole package

- Designed for wet or dry, non-corrosive media

Applications

- Liquid level measurement systems

- Flow rate monitoring equipment

- Pressure indication and control assemblies

- Irrigation and water control valves

- Robotics and automation platforms

- Leak detection and filter monitoring

Frequently Asked Questions

Is this sensor internally amplified?

No. The 26PCAFA6D provides a low-level millivolt output and requires external amplification.

Can it measure both vacuum and pressure?

Yes. The sensor supports vacuum or positive pressure depending on port configuration.

What makes the 26PC Series interchangeable?

Factory calibration and temperature compensation allow consistent performance across units.

Is it suitable for wet media?

The design supports wet/wet differential sensing when used with compatible, non-corrosive fluids.

You can monitor liquid level changes by connecting clean tubing to both ports and routing the temperature-compensated bridge output through an instrumentation amplifier mounted directly on your PCB.