Product Overview

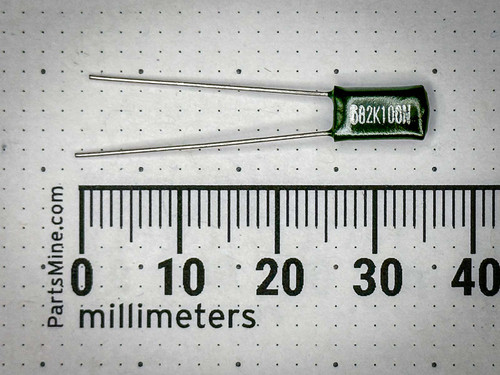

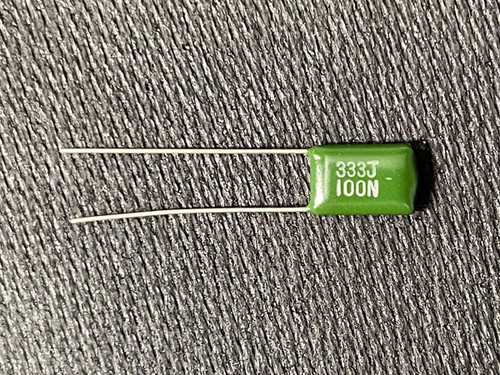

2.2nF 100V Through-Hole Film Capacitor (222K100N)

Product Overview

This high-quality film capacitor is designed for reliability and consistent performance across a wide range of electronic applications. With a capacitance of 2.2nF and a voltage rating of 100V, it's an excellent choice for various circuit designs in both consumer and industrial electronics.

Key Specifications

- Capacitance: 2.2nF (nanofarads)

- Voltage Rating: 100V

- Product Code: 222K100N

- Tolerance: Likely ±10% (indicated by 'K' in the product code)

Applications

This versatile film capacitor is ideal for:

- Filtering and smoothing circuits

- Timing and oscillator circuits

- Coupling and decoupling in audio and RF circuits

- Motor run and start applications

Why Choose This Capacitor?

Film capacitors are known for their:

- Stability across varying conditions

- Low losses, especially at high frequencies

- Reliability and long operational life

- Excellent performance in demanding applications

Sustainability Note

By choosing this capacitor from PartsMine, you're supporting the reuse and repurposing of quality electronic components, contributing to a more sustainable approach in electronics manufacturing and repair.

Film Capacitor FAQ

What makes film capacitors unique?

Film capacitors use a thin plastic film as the dielectric, giving them several unique properties:

- Non-polarized design suitable for both AC and DC applications

- Excellent frequency characteristics and low losses

- High insulation resistance and voltage ratings

- Self-healing capability for improved reliability

- Long operational life and stability over time

How does the self-healing property of film capacitors work?

The self-healing mechanism is a key advantage of metallized film capacitors. If a small defect or breakdown occurs in the dielectric:

- The breakdown causes a brief short circuit

- The high current vaporizes a small area of the metallized electrode around the defect

- This creates an insulating area, effectively "healing" the capacitor

- The capacitor continues to function with only a slight reduction in capacitance

What are the main types of plastic films used in film capacitors?

Common dielectric materials include:

- Polypropylene (PP) - Low losses, excellent stability

- Polyethylene terephthalate (PET) - High dielectric constant, compact size

- Polyphenylene sulfide (PPS) - High temperature resistance

- Polytetrafluoroethylene (PTFE) - Excellent high-frequency performance

How do film capacitors compare to other capacitor types?

| Characteristic | Film Capacitors | Ceramic Capacitors | Electrolytic Capacitors |

|---|---|---|---|

| Capacitance range | 100 pF to 30 µF | 1 pF to 100 µF | 0.1 µF to 1 F |

| Voltage rating | 50V to 2000V+ | 25V to 1000V | 6.3V to 450V |

| Frequency performance | Excellent | Good to Excellent | Poor |

| Stability | Very good | Varies | Poor |

| Size (for given capacitance) | Medium | Small | Large |

What are some unique applications of film capacitors?

Film capacitors excel in several specialized applications:

- Snubber circuits in power electronics

- High-current pulse applications (e.g., in lasers or medical equipment)

- AC motor run capacitors

- Safety-rated capacitors for EMI suppression

- High-reliability aerospace and military equipment

Did you know?

Film capacitors can handle voltage spikes up to 2-3 times their rated voltage for short durations, making them ideal for protecting sensitive electronics from power surges.