Product Overview

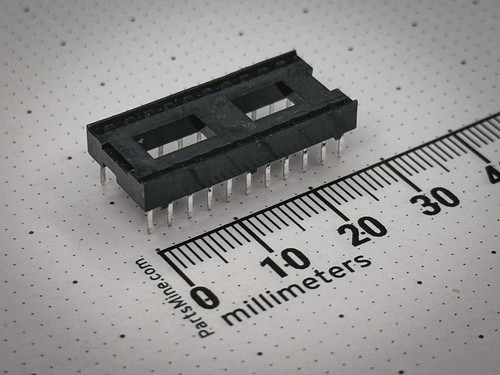

Through-Hole 24P Dual Inline Socket for ROM and EPROM Chips

Product Condition

Unused, New Old Stock.

Ships same business day. Reliable parts at honest prices since 1999. Real humans.

Product Overview

24-pin DIP IC socket designed for through-hole solder mounting. Accepts standard 24-pin Dual Inline Package integrated circuits including ROMs, EPROMs, EEPROMs, and logic devices in 0.6 inch row spacing. Sockets allow chips to be installed and removed without repeated heat exposure to the device, reducing risk during prototyping, repair, or field replacement. Commonly used on vintage computer boards, industrial control cards, and custom embedded builds.

Through-hole solder tails mount directly to printed circuit boards with standard 0.1 inch pitch hole patterns typical of DIP layouts.

Key Features

- 24-pin Dual Inline Package configuration

- Through-hole solder termination

- Standard 0.1 inch (2.54 mm) pin pitch

- Standard 0.6 inch row spacing for 24P DIP

- Compatible with ROM, EPROM, EEPROM, and logic ICs

- Allows chip replacement without desoldering the IC

- Suitable for prototyping and permanent PCB assembly

- Mechanical alignment notch for orientation reference

Applications

- Vintage computer motherboard repair

- EPROM programming and development boards

- Industrial control PCB servicing

- Microcontroller and memory prototyping

- Educational electronics labs

- Custom embedded system builds

- Field-serviceable circuit designs requiring socketed ICs

Frequently Asked Questions

Will this fit standard 24-pin DIP chips?

Yes. It is designed for standard 24-pin Dual Inline Package ICs with 0.1 inch pin spacing and 0.6 inch row spacing.

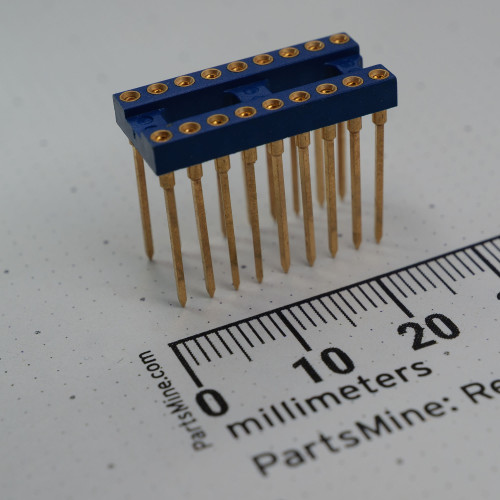

Is this machine-pin or stamped contact?

The listing is for a 24-pin through-hole solder type DIP socket. If you need confirmation on contact style, please confirm before ordering.

Can this be used for EPROMs like 27C series devices?

Yes, as long as the device uses a standard 24-pin 0.6 inch DIP package.

Is this suitable for high-frequency applications?

DIP sockets introduce additional contact resistance and lead length compared to direct soldering. For most logic and memory applications, they are appropriate within typical DIP device operating ranges.

Do you have more available?

Available quantity reflects current stock on hand.

Simple component, critical role. If you are socketing memory or keeping a legacy board serviceable, this is the small detail that makes future repairs easy.

![Vintage Samsung KS82C54-10CP Programmable Interval Timer IC, 24-Pin DIP [[product_type]] PartsMine Vintage Samsung KS82C54-10CP Programmable Interval Timer IC, 24-Pin DIP [[product_type]] PartsMine](https://cdn11.bigcommerce.com/s-cl52ybm741/images/stencil/500x659/products/3719/8277/Vintage-Samsung-KS82C54-10CP-Programmable-Interval-Timer-IC-24-Pin-DIP-producttype_8264__34888.1736989147.jpg?c=2)